Welcome to Advanced Resin Printing: A New Dimension in 3D Printing

Welcome to Ripley Dynamics, where we are pioneering a new dimension in 3D printing with our advanced resin printing services in Australia. Resin printing, a groundbreaking technology in the 3D printing world, offers unparalleled precision and detail, opening up new possibilities for creators, designers, and businesses alike. Unlike traditional 3D printing techniques, our resin printing process uses photopolymerization, where UV light cures liquid resin layer by layer to create intricate, high-quality objects. This method allows for finer details, smoother surfaces, and a higher degree of accuracy, making it ideal for applications where precision is paramount.

At Ripley Dynamics, we are committed to pushing the boundaries of what's possible with 3D printing. Our state-of-the-art UV resin printers are capable of producing complex geometries and delicate features that other printing methods can't achieve. Whether you are an artist looking to bring your sculptures to life, a medical professional needing accurate anatomical models, or an engineer designing intricate components, our advanced resin printing services can turn your vision into reality with unmatched clarity and precision.

Understanding Resin-Based 3D Printing: Applications and Advantages

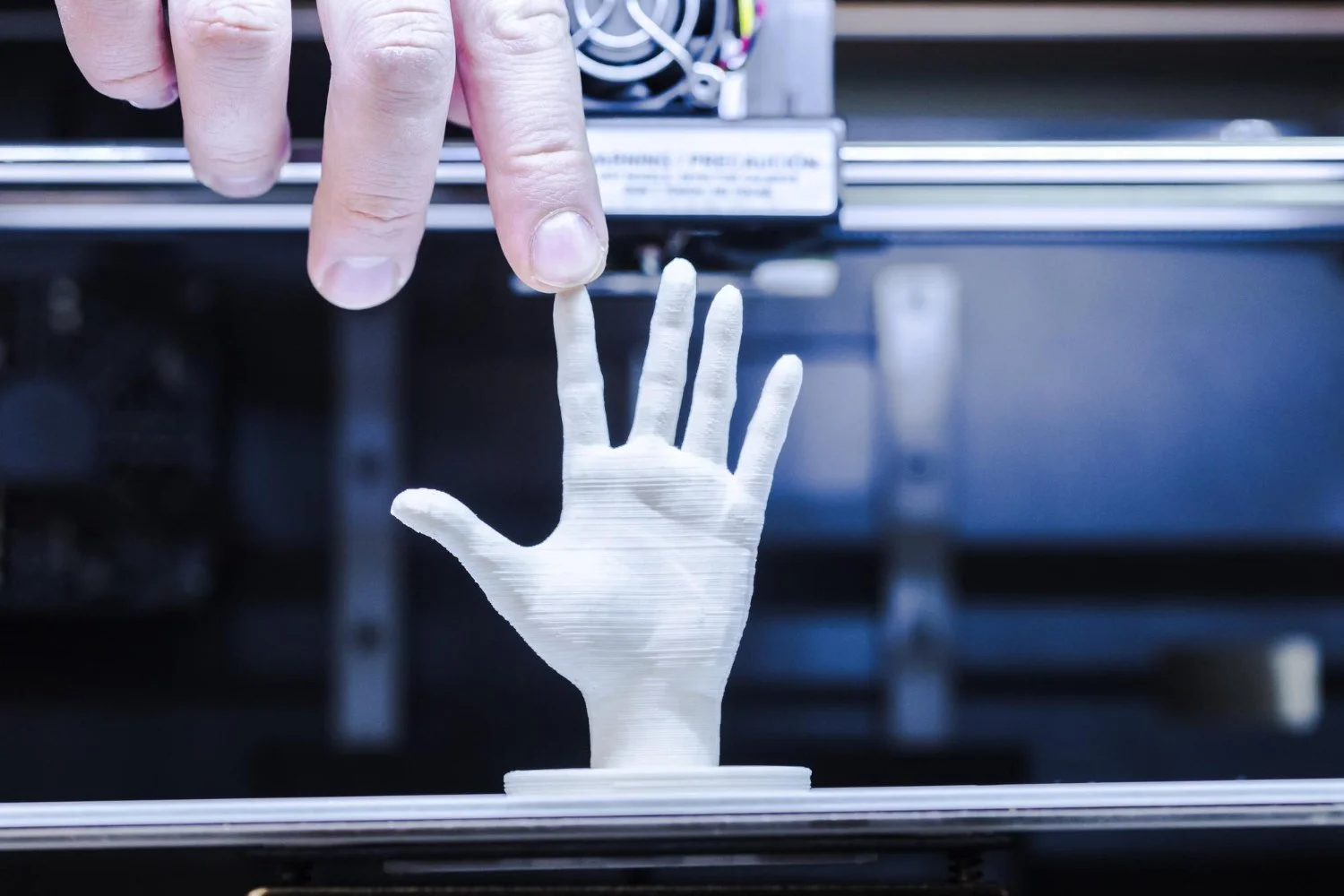

Resin-based 3D printing, offered by Ripley Dynamics, stands at the forefront of precision additive manufacturing. This technology uses liquid resin, which is cured and solidified by UV light, to create objects with exceptionally high resolution and detail. One of the most significant advantages of resin-based printing is its capability to produce parts with intricate details and a smooth surface finish, which is particularly beneficial for industries where precision is crucial, such as in dental and medical applications, jewelry design, and engineering prototypes.

The applications of resin printing are vast and varied. In the medical field, it's used for creating detailed anatomical models for surgical planning and education. For artists and designers, resin printing offers the ability to transform complex digital designs into tangible art with fine features and clear textures. In the realm of prototyping and manufacturing, it allows for the creation of precise and robust parts with a quality finish, suitable for functional testing and end-use products.

With Ripley Dynamics’ expertise in resin-based 3D printing, clients across Australia can leverage these advantages for a wide range of applications. We provide a seamless, quality-driven printing service that ensures your designs are brought to life with the utmost accuracy and detail.

When to Choose Resin Printing Services: Identifying the Ideal Scenarios

Choosing resin printing services from Ripley Dynamics is ideal for specific scenarios where the unique capabilities of resin 3D printing align with the project's requirements. Resin printing is the go-to option when you need ultra-high resolution and intricate detail. This makes it perfect for applications such as jewelry design, where the precision of small, detailed features is paramount, or for creating detailed miniatures and models for architectural or artistic projects.

Another scenario where resin printing excels is in the production of prototypes and end-use parts with complex geometries that traditional manufacturing methods can't achieve. This includes thin walls, intricate lattice structures, and detailed textures. Additionally, resin printing is highly beneficial in the medical and dental fields for creating accurate anatomical models, dental aligners, and hearing aids, which require a high degree of precision and a smooth surface finish.

When your project demands exceptional detail, a high-quality surface finish, or intricate designs that are difficult to realize with other 3D printing technologies, Ripley Dynamics’ resin printing services in Australia are your ideal choice. Our expertise ensures that even the most complex designs are executed with precision, meeting the highest standards of quality and functionality.

Exploring the World of UV Resin 3D Printers

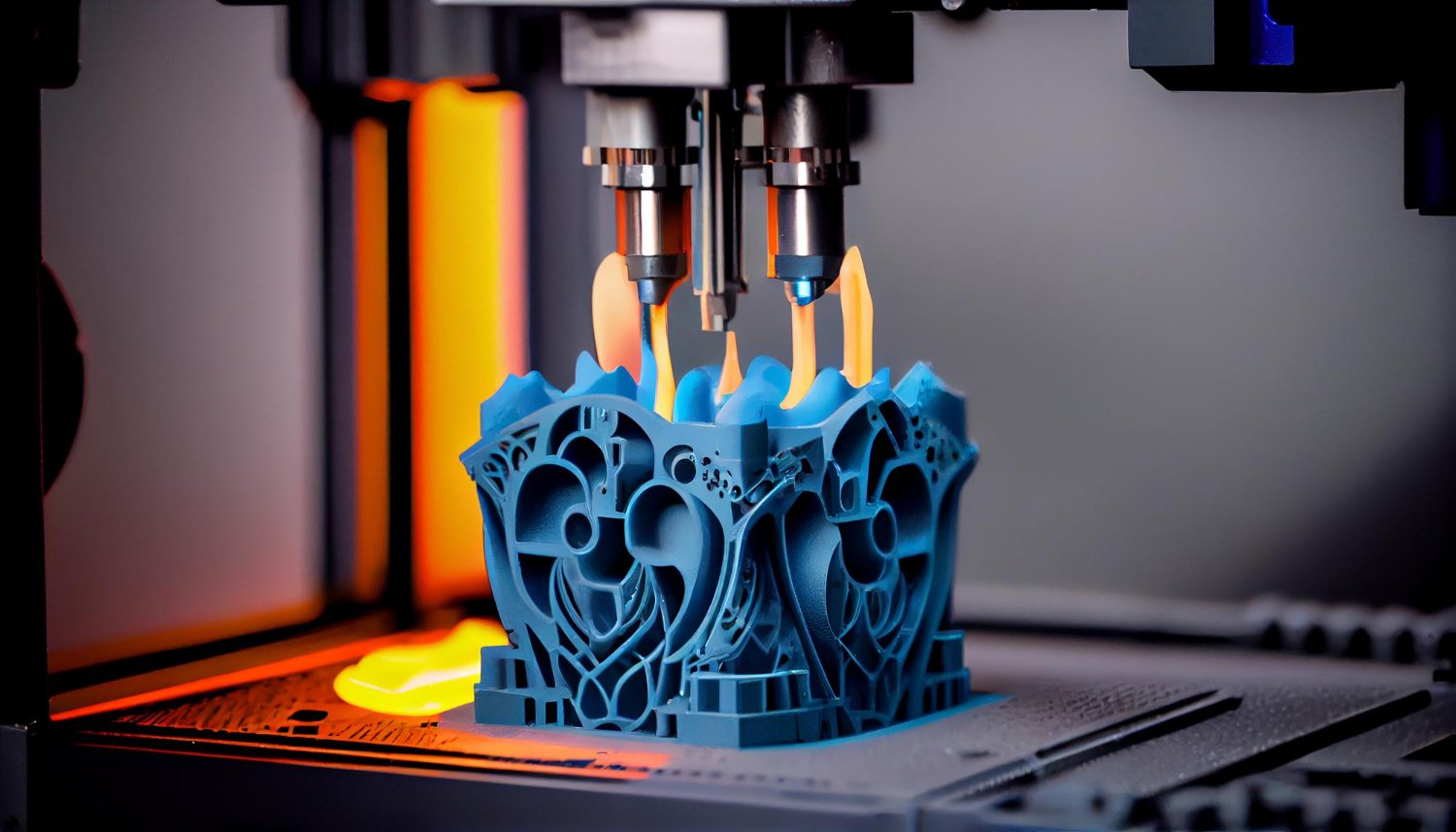

At Ripley Dynamics, we delve into the innovative world of UV resin 3D printers, a technology that has revolutionized the field of additive manufacturing. UV resin 3D printers operate on the principle of curing liquid photopolymer resin using ultraviolet light, layer by layer, to build highly detailed and precise objects. This technology stands out for its ability to produce parts with incredibly fine details and smooth surfaces, which is difficult to achieve with filament-based 3D printing methods.

One of the key benefits of UV resin printing is its speed and efficiency in producing small to medium-sized parts. It's particularly well-suited for applications requiring high detail, such as prototyping for consumer products, creating intricate art pieces, or manufacturing detailed components for electronics. The versatility of resin materials also allows for a range of properties in the final print, from rigid and strong to flexible and clear.

Ripley Dynamics harnesses this cutting-edge technology to provide clients across various industries in Australia with prints that showcase exceptional detail, precision, and quality. Whether for prototyping, production, or artistic creation, our UV resin 3D printers are capable of transforming complex digital designs into tangible, high-quality objects.

High-Resolution Resin Printing: Precision and Quality in Every Print

High-resolution resin printing is the hallmark of Ripley Dynamics’ 3D printing services, setting a standard of precision and quality in every print. This method is characterized by its extraordinary level of detail, capable of producing features as fine as a few microns across. Such precision is essential in fields where the smallest detail can have a significant impact, like in dental appliances, intricate jewelry, and precision engineering components.

Our high-resolution resin printing process ensures that every layer of your design is rendered with the utmost clarity and accuracy, resulting in a product that closely matches your original vision and design specifications. The smooth surface finish achieved through this method also minimizes the need for post-processing, saving time and effort in the final stages of production.

Whether you are creating a prototype that needs to closely mimic the final product, or a complex component with detailed features, Ripley Dynamics’ high-resolution resin printing service is the solution you need. We are committed to delivering prints that not only meet but exceed your expectations for precision and quality, ensuring your projects in Australia are a resounding success.

The Journey of Stereolithography: From Concept to Reality

Stereolithography (SLA), a process at the heart of Ripley Dynamics’ resin printing services, represents the transformation of a concept into reality through advanced technology. This journey begins with a digital 3D model, which SLA brings to life by converting liquid resin into a solid object, layer by meticulous layer. The process involves a UV laser precisely tracing the object’s cross-section on the surface of liquid resin, causing it to harden and take shape. As the build platform moves, each subsequent layer bonds to the previous one, creating a highly detailed and accurate three-dimensional object.

This technology is celebrated for its ability to produce objects with exceptionally fine details and smooth surface finishes, surpassing the capabilities of other forms of 3D printing. It is especially beneficial for applications requiring intricate designs, such as intricate prototypes, custom dental work, and detailed miniatures. The precision and detail achievable with SLA make it an invaluable tool for professionals and hobbyists alike, turning complex digital designs into tangible, high-quality objects with Ripley Dynamics’ expert touch in Australia.

Selecting the Strongest Resins for Superior 3D Printing Results

At Ripley Dynamics, selecting the strongest and most suitable resins is pivotal to achieving superior 3D printing results. The choice of resin impacts not only the print’s detail and accuracy but also its functional properties like strength, flexibility, and temperature resistance. Our expertise in this selection process ensures that each project is matched with the optimal resin to meet its specific requirements.

We offer a diverse range of resins, including standard resins for general use, tough resins for parts requiring high strength and durability, and flexible resins for objects needing a certain degree of pliability. For more specialized applications, we provide castable resins for jewelry and dental use, and high-temperature resins for components that must withstand extreme conditions. Each resin type is chosen based on its properties to ensure that the final print not only looks exceptional but also performs excellently in its intended application. This meticulous selection process is a cornerstone of Ripley Dynamics’ commitment to delivering top-tier resin 3D printing services in Australia.

Resin Polymerization Process: The Science Behind Quality Prints

The resin polymerization process is the scientific foundation of high-quality prints in resin 3D printing, a cornerstone of Ripley Dynamics’ services. This process involves curing liquid photopolymer resins into solid plastic through a controlled UV light exposure. When the UV light hits the resin, it initiates a chemical reaction that causes the resin molecules to link together, transforming from a liquid to a solid state.

This polymerization process is meticulously controlled to achieve the desired properties in the final print. Factors like the intensity of the UV light, the exposure time, and the type of resin used play critical roles in determining the strength, flexibility, and resolution of the print. Advanced technology in our UV resin 3D printers allows precise control over these factors, ensuring each layer of resin is cured to perfection.

The science behind resin polymerization is what allows Ripley Dynamics to produce prints with remarkable detail, smooth finishes, and robust physical properties. This process is key to transforming intricate designs into tangible objects with unparalleled precision and quality, a hallmark of our resin printing services in Australia.

Customization and Quality Control in Resin Printing Services

Customization and quality control are essential aspects of Ripley Dynamics’ resin printing services, ensuring that each print meets the unique needs and high standards of our clients. Our resin printing process offers a high degree of customization, from choosing the appropriate resin type to adjusting printing parameters like layer thickness and exposure times. This flexibility allows us to tailor each project to the specific requirements of our clients, whether it's for detailed prototypes, artistic creations, or functional parts.

Quality control is rigorously implemented throughout the printing process. We conduct thorough checks at every stage, from the initial design assessment to the final post-processing steps. Our team ensures that the digital model is optimized for printing, and the print settings are fine-tuned for the best results. Post-printing, each object undergoes a comprehensive inspection to verify its accuracy, detail, and structural integrity. This commitment to customization and quality control is what sets Ripley Dynamics apart, ensuring that each resin print from our facility in Australia stands out for its precision, quality, and reliability.

The Future of Resin Printing: Technology Advancements and Materials Exploration

The future of resin printing is an exciting frontier, marked by continual technology advancements and materials exploration, areas where Ripley Dynamics is actively engaged. The evolution of resin printing technologies promises even finer resolutions, faster printing speeds, and greater material capabilities. Advances in printer hardware and UV light sources are expected to enhance the precision and efficiency of the printing process, opening up new possibilities for complex, high-quality prints.

In terms of materials, ongoing research and development are expanding the range of resins available, each with unique properties suited to specific applications. Future resins may offer enhanced functionalities, such as improved strength, flexibility, heat resistance, or biocompatibility, broadening the scope of industries and applications that can benefit from resin printing.

Environmental sustainability is also a growing focus in resin printing. Developing eco-friendly resins and recycling methods for resin waste are crucial steps towards minimizing the environmental impact of 3D printing.

Ripley Dynamics is at the forefront of these advancements, continually incorporating the latest innovations in resin printing technology and materials. We are committed to evolving our services to meet the changing needs of our clients in Australia, ensuring that we remain a leader in delivering cutting-edge resin printing solutions.