Introducing Our Vacuum Casting Services: Precision Prototyping in Australia

Ripley Dynamics is proud to introduce our vacuum casting services, a key offering in precision prototyping within Australia. This process is ideal for producing high-quality, accurate replicas of prototypes in a cost-effective and timely manner. Vacuum casting is particularly suited for small to medium batch production, making it a perfect choice for businesses and innovators who require quick turnarounds for their prototypes or limited-run products.

Our state-of-the-art vacuum casting technology enables us to produce parts with exceptional detail and surface finish. This technique is versatile enough to work with a wide range of materials, allowing us to mimic the properties of various plastics, including ABS, polycarbonate, and rubber-like materials. Whether it’s for consumer electronics, automotive components, or medical devices, our vacuum casting services can cater to diverse industry needs.

At Ripley Dynamics, we are dedicated to providing our clients with prototypes that not only look and feel like the final product but also meet the rigorous standards of functionality and quality, all while ensuring a quick turnaround time.

The Process of Vacuum Casting: From Silicone Molds to Resin Casting

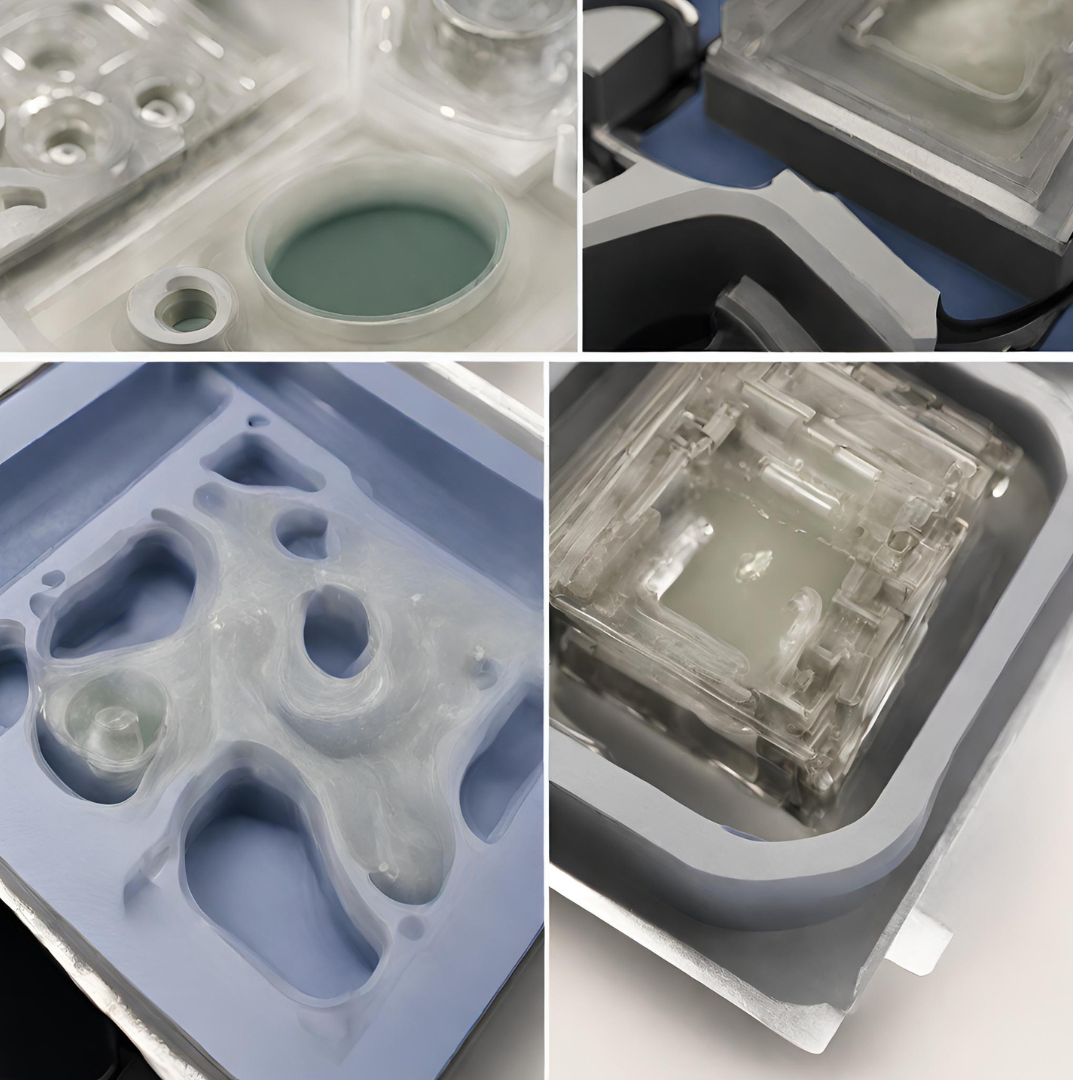

The process of vacuum casting, offered by Ripley Dynamics, is a refined and efficient method for producing high-quality prototypes and end-use parts. The process starts with the creation of a master model, usually fabricated using high-resolution 3D printing. This model is then used to create a silicone mold, capturing even the finest details with exceptional accuracy.

Once the silicone mold is ready, it is placed in a vacuum chamber where the casting resin is introduced. The vacuum environment is crucial as it ensures the resin fills every part of the mold evenly, eliminating air bubbles and defects for a superior finish. After the resin cures, the mold is opened to reveal a highly accurate replica of the original master model.

This process can be repeated multiple times, making vacuum casting a cost-effective solution for producing small to medium batches of parts. With a wide range of casting resins available, different material properties can be achieved, from rigid and robust to flexible and transparent, giving our clients a variety of options for their specific application needs.

Polyurethane Vacuum Casting: Crafting Durable and Detailed Prototypes

Polyurethane vacuum casting is a specialized service offered by Ripley Dynamics, ideal for crafting durable and detailed prototypes. This technique uses polyurethane resins to produce parts that closely mimic the properties of injection-molded plastics. This method is excellent for creating prototypes that not only look like the final product but also behave similarly in terms of strength, flexibility, and thermal properties.

The versatility of polyurethane resins allows for a wide range of material characteristics, including varying degrees of rigidity, transparency, and heat resistance. This makes it possible to cater to specific prototype requirements across diverse industries, including automotive, medical, and consumer products.

Our expertise in polyurethane vacuum casting ensures that each prototype is produced with the utmost attention to detail, replicating complex geometries and textures accurately. This process is particularly advantageous for functional testing, aesthetic models, and low-volume production, providing our clients with quick, cost-effective, and high-fidelity prototypes.

Understanding Vacuum Casting Costs and Benefits for Your Project

Understanding the costs and benefits of vacuum casting is crucial for making informed decisions about your prototyping projects. At Ripley Dynamics, we believe in transparency and helping our clients comprehend the value that vacuum casting brings. One of the primary benefits of vacuum casting is its cost-effectiveness, especially for small to medium production runs. It eliminates the need for expensive tooling associated with traditional manufacturing, significantly reducing the upfront costs.

The versatility of vacuum casting also means that a wide range of materials can be used, allowing for the production of parts with specific characteristics at a relatively lower cost compared to other methods. Moreover, the quality and detail that can be achieved with vacuum casting are exceptional, ensuring that prototypes are not only functional but also aesthetically pleasing.

When considering vacuum casting for your project, our team at Ripley Dynamics works closely with you to provide a detailed cost analysis, ensuring you understand the investment and the potential returns. This includes considering factors such as the complexity of the design, the choice of materials, and the quantity of parts required, all tailored to fit your project's specific needs.

Advanced Mold Making Techniques in Vacuum Casting

Advanced mold-making techniques are at the heart of vacuum casting services at Ripley Dynamics. Our approach combines traditional craftsmanship with modern technology to create high-precision silicone molds, essential for producing detailed and accurate resin parts. Our expertise lies in understanding the intricacies of mold design, including parting lines, gates, vents, and overmolding requirements, which are crucial for achieving optimal casting results.

We employ the latest in 3D printing and CNC machining to create master patterns, ensuring that the molds produced are of the highest fidelity. This allows for complex geometries, intricate details, and textured surfaces to be replicated flawlessly. Our mold-making process also considers factors like thermal expansion and material shrinkage, ensuring dimensional accuracy in the final cast parts.

Our team’s skill in advanced mold-making, combined with our deep knowledge of materials and casting processes, enables us to produce prototypes and parts that meet the stringent requirements of industries such as automotive, aerospace, medical devices, and consumer products. With Ripley Dynamics, clients are assured of receiving molds and parts that are not only of high quality but also tailor-made to suit their specific prototyping needs.

Choosing the Right Materials for Your Vacuum Casting Needs

Selecting the appropriate materials for vacuum casting is a crucial step in achieving the desired outcome for your prototypes, and Ripley Dynamics is well-equipped to guide you through this process. The material chosen for vacuum casting impacts not only the look and feel of the final product but also its functionality and performance. We offer a wide range of polyurethane resins that mimic the properties of various plastics, rubbers, and even metals.

Each resin has unique characteristics in terms of strength, flexibility, temperature resistance, and color. For instance, some resins are suited for parts that need to be rigid and strong, while others are more appropriate for items that require a degree of flexibility or transparency. We also provide materials with specialized properties like flame retardancy or UV resistance, essential for specific industry applications.

Our team works closely with clients to understand the specific requirements of their projects, whether it’s for automotive components, medical devices, or consumer products. Based on these needs, we recommend the most suitable materials to ensure the vacuum casted prototypes not only meet but exceed expectations.

Achieving High-Quality Results with Precision Vacuum Casting

Achieving high-quality results is a hallmark of precision vacuum casting services at Ripley Dynamics. Our process is meticulously designed to produce detailed, accurate, and aesthetically pleasing prototypes. We employ advanced vacuum casting techniques to ensure each prototype is free of air bubbles and defects, which is essential for achieving the highest level of detail and surface finish.

The process begins with the creation of a high-quality master model, typically using 3D printing. This model is then used to produce a silicone mold that precisely captures every detail. The precision in mold making is mirrored in the casting process, where we carefully control the temperature and pressure to ensure consistent results.

Our expertise in vacuum casting enables us to produce parts that not only match the design specifications but also possess excellent mechanical properties. This precision makes our vacuum casting service ideal for functional prototypes, aesthetic models, and small production runs where quality cannot be compromised.

The Advantages of Using Vacuum Casting for Prototype Fabrication

Vacuum casting offers several significant advantages for prototype fabrication, making it a popular choice for designers and engineers. One of the key benefits is the ability to produce high-quality prototypes quickly and cost-effectively. This method is ideal for small to medium batches, where it is more economical than traditional manufacturing methods.

Another advantage of vacuum casting is its versatility in material choice. It allows for a wide range of materials with various colors, textures, and mechanical properties, enabling the creation of prototypes that closely resemble the final product. This method is particularly useful for testing the functionality and aesthetics of a design before committing to mass production.

Furthermore, vacuum casting is known for producing parts with excellent detail and surface finish, which is crucial for consumer-facing products where visual appeal is essential. At Ripley Dynamics, we utilize vacuum casting to provide our clients with prototypes that are not only functional but also visually impressive, helping them to validate their designs effectively.

Custom Surface Finishes: Elevating the Quality of Vacuum Casted Products

At Ripley Dynamics, we understand that the final appearance of a vacuum casted product is as important as its functionality. Therefore, we offer custom surface finishes to elevate the quality of our vacuum casted products. Our range of finishing options allows prototypes to closely resemble the end product, making them ideal for market testing, presentations, and functional testing.

Options for surface finishing include painting, which can be color-matched to specific requirements, texturing to mimic different materials, and polishing for a high-gloss appearance. We also offer more specialized finishes like metallic or rubberized coatings, which not only enhance the aesthetic appeal but can also provide additional functional properties like improved grip or increased durability.

Our team works closely with clients to understand their specific needs and advises on the best surface finishing techniques to optimize the appearance and functionality of their vacuum casted prototypes, ensuring they meet both aesthetic and practical requirements.

When to Opt for Vacuum Casting: Flexible Solutions for Product Development

Vacuum casting is an incredibly flexible solution in product development, ideal for various scenarios. It is particularly well-suited for situations where high-quality, detailed prototypes are needed quickly, and in quantities that are not large enough to justify the cost of injection molding tooling. This makes vacuum casting a cost-effective option for small to medium production runs.

This technique is also beneficial when the product requires specific material properties that are achievable through the wide range of resins available in vacuum casting. Whether it’s for creating parts that mimic different types of plastics or need to be transparent, flexible, or rigid, vacuum casting can meet these requirements.

Additionally, vacuum casting is the go-to method when prototypes need to be as close to the final product as possible, in terms of detail, texture, and material properties. This is crucial for functional testing, consumer testing, and marketing purposes.

Ripley Dynamics recommends vacuum casting for projects requiring flexibility, speed, and high-quality results, making it a valuable tool in the product development process.