Unleash Precision: Explore the Power of SLA 3D Printing

SLA (Stereolithography Apparatus) technology is renowned for its precision and versatility. Ripley Dynamics, a leading SLA 3D printing provider in Sydney and Australia, has revolutionized additive manufacturing. Our SLA printing service is not just about creating objects; it's about transforming your ideas into tangible realities. Stereolithography 3D printing, a form of resin printing, uses ultraviolet light to cure and solidify layers of photo-sensitive resin. This method allows for a higher level of detail and finish than other 3D printing techniques.

Custom Solutions with Ripley Dynamics' SLA Printing Service

Ripley Dynamics offers a comprehensive range of SLA 3D printing services, catering to various needs - from rapid prototyping to custom parts production. Our SLA 3D printing online platform simplifies the process, making it accessible and efficient. Whether you need a single prototype or a batch of intricate components, our SLA printing service price is competitive. This ensures you get the best value without compromising on quality.

Optimized Processes for Rapid Turnaround and Quality

Our SLA 3D printing technology is not just a service; it's a solution. We understand the challenges of transforming a concept into a physical object. That's where our expertise in SLA 3D printing custom parts comes into play. Our process is meticulously designed to cater for your specific needs. With SLA 3D printing on demand, we ensure quick turnaround times, essential in today's fast-paced market.

Material Selection for Perfect Results

Choosing the right SLA 3D printing materials is crucial for your project's success. Ripley Dynamics offers a variety of options, each with unique properties and applications. Whether you need high strength, flexibility, or transparency, we have you covered. Our team works closely with you to select the best material, ensuring your project's success.

SLA 3D printing with Ripley Dynamics has benefits beyond high-quality parts production. Our SLA 3D printing services are designed to be cost-effective, reducing expensive tooling and minimizing waste. This makes SLA an ideal choice for small to medium-sized businesses looking to innovate without significant investment.

Exploring the Advantages and Challenges of SLA Technology

Stereolithography 3D printing's advantages are numerous. The technology allows for complex geometries and fine details, which are often impossible to achieve with traditional manufacturing methods. This capability opens up a world of possibilities in various applications, from medical devices to custom jewelry. However, it's important to understand stereolithography 3D printing's drawbacks as well. One of the limitations is the size of the printing area, which may restrict the dimensions of the objects you can produce. Additionally, while the range of materials available for SLA printing is expanding, it is still limited than other forms of 3D printing.

Innovative Solutions and Exceptional Service at Ripley Dynamics

Ripley Dynamics addresses these challenges by constantly innovating and expanding our SLA 3D printing applications. Our team stays at the forefront of the latest developments in SLA technology, ensuring our clients have access to the most comprehensive solutions available. In conclusion, Ripley Dynamics is more than just an SLA 3D printing company. We are a partner in your creative and manufacturing journey. Our commitment to quality, combined with competitive SLA 3D printing costs and exceptional customer service, makes us the go-to choice for all your SLA printing needs. Contact us today for an SLA 3D printing quote and experience the transformative power of SLA technology with Ripley Dynamics.

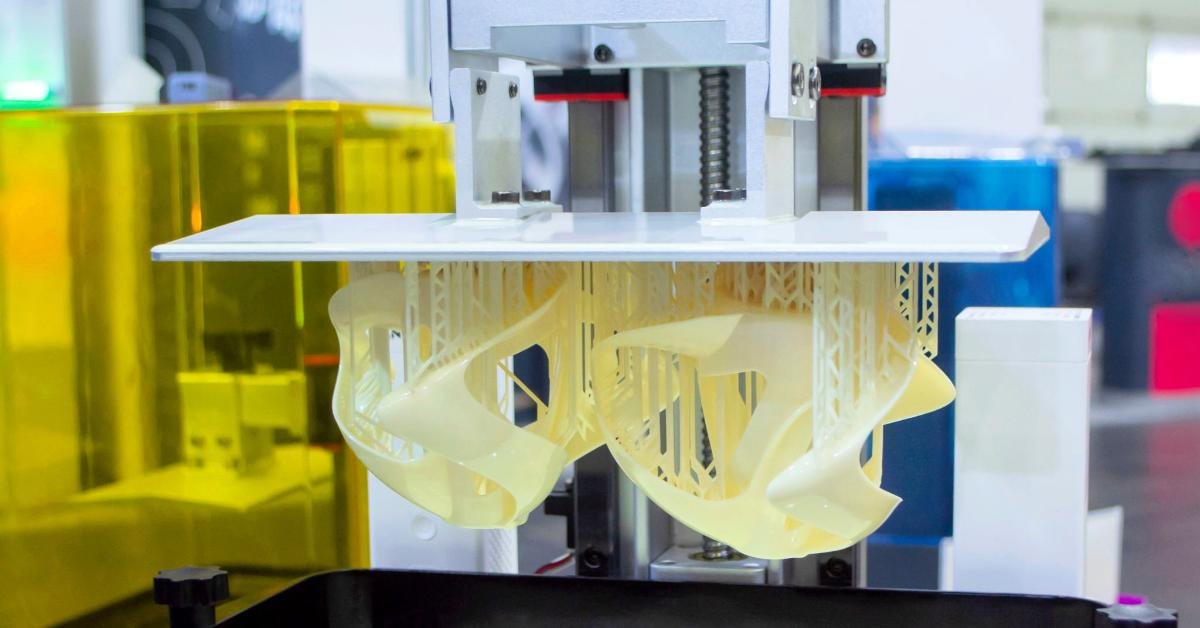

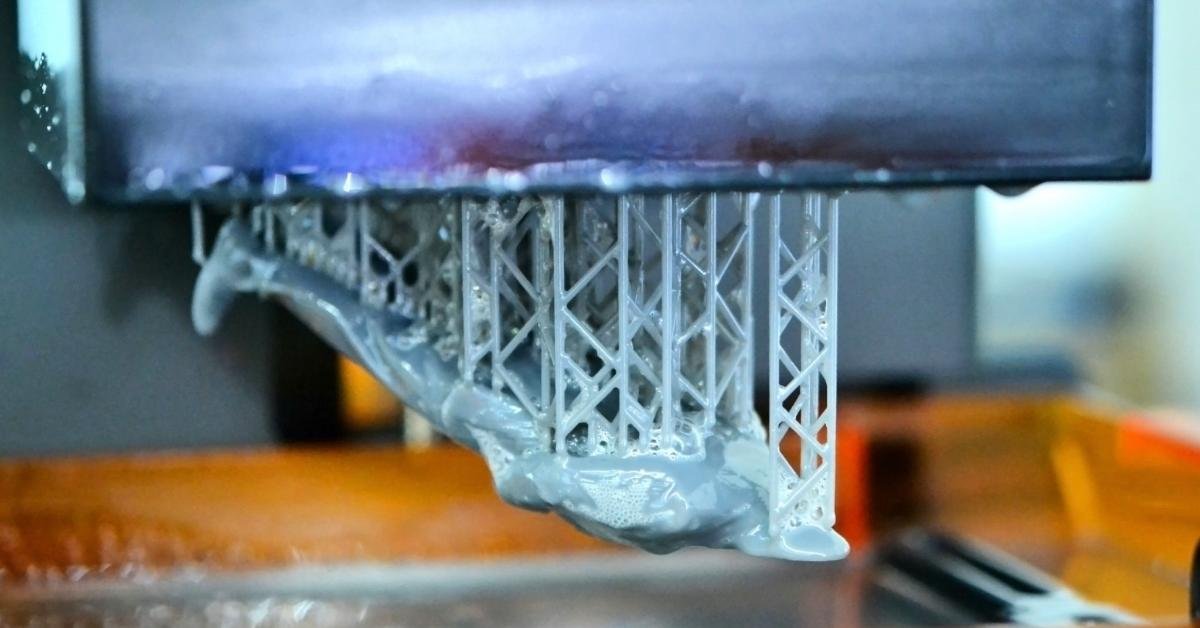

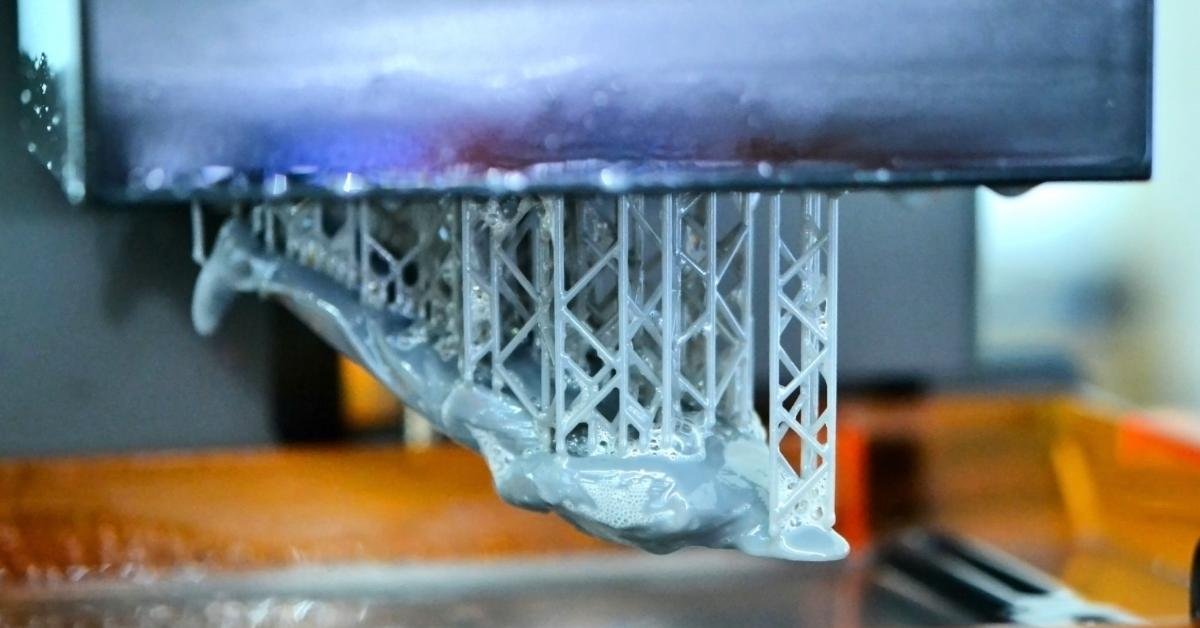

The SLA 3D Printing Process

Understanding the SLA 3D printing process is key to appreciating the intricacies and benefits of this technology. Ripley Dynamics prides itself on a streamlined, efficient process that ensures quality and precision in every print. The first step in our SLA printing workflow involves detailed planning and design. Our clients provide their ideas or 3D models, which our team reviews for printability. Using advanced software, we optimize these designs for the SLA process, considering factors like orientation, support, and resolution.

Once the design is finalized, we select the appropriate resin. This choice is critical as it impacts the mechanical properties, finish, and durability of the final product. Our range of resins includes options for various applications, ensuring we meet the specific requirements of each project.

The actual printing process in SLA involves a laser that precisely cures the resin layer by layer. This step is where the magic happens, transforming digital models into physical objects with exceptional detail. Our state-of-the-art printers maintain optimal conditions to ensure consistent quality.

Post-processing is the final stage in our workflow. After printing, the parts undergo cleaning to remove any uncured resin. Further post-processing steps like curing, sanding, or painting are performed based on the project needs. This attention to detail in post-processing ensures that the final product not only meets but exceeds client expectations.

SLA 3D Printing: Wide Range of Uses

SLA 3D printing technology finds its application in a wide array of industries, each benefiting from its precision and versatility. In the medical field, SLA printing is used to create detailed anatomical models for surgical planning and medical training. These models can replicate patient-specific anatomy, aiding in more precise and effective treatments.

In the field of dentistry, SLA 3D printing is revolutionizing practices with the production of dental models, orthodontic devices, and even custom crowns. The ability to produce these items in-house significantly reduces the time and cost for dental professionals and patients.

The aerospace industry benefits from SLA printing in creating lightweight, complex components. The precision of SLA is crucial in an industry where every millimeter and gram counts. Similarly, the automotive industry utilizes SLA for prototyping and producing end-use parts that require high detail and durability.

In consumer goods, SLA 3D printing enables the creation of intricate, high-quality items such as jewelry, eyewear, and fashion accessories. The technology's ability to produce smooth, detailed parts makes it ideal for these high-aesthetic applications.

SLA 3D printing is also instrumental in creating intricate models and prototypes for architectural and engineering projects. Its capacity to accurately reproduce fine details and complex geometries helps professionals visualize and test their designs more effectively.

Ripley Dynamics' expertise in SLA 3D printing positions us at the forefront of these diverse applications. Our commitment to quality, innovation, and customer satisfaction ensures that whatever the application, we deliver products that not only meet but exceed the expectations in functionality and aesthetics.